blown film machine pdf

However a review of the process of blown film extrusion is worthwhile. Full PDF Package Download Full PDF Package.

Wenzhou Aoxiang Packaging Machinery Co Ltd

The re- sulting biaxial stress can further induce crystalliza- tion an action termed flow-induced crystallization.

. The polymer is melted in an extruder and the hot melt is pumped through a die to form. The undertaking of this project is so large that it had to be approached a step at a time. Blown film towers require large vertical heights.

SmartFlex Blown Film lines 1 3 and 5 layers characterized by a competitive investment level maximized flexibility for different applicationsrecipes power consumption reduction functional and compact layout featuring frames modularity. The purpose of the blown film die is to receive polymer melt from the extruder and deliver it to the die exit as a thin annular tubular film. Blown Film Troubleshooting Guide Bubble Instability Chatter Die Lines Poor Heat Seal Melt Fracture Gauge V ariation cont Gels Causess Possible Solutions Dirty Air Ring Cont Check the seal between the air ring and die Check hoses for kinks or bends restricting air flow Surging of the extruder Check drive speed of the extruder.

Machine Construction A cut-away drawing of a simple single screw machine is shown in Figure 1. This type of extrusion utilizes. This shows the arrangement of the different parts of the machine.

The blown film process is capable of. As a Blown Film Plant Manufacturer and Blown Film Extrusion Machine Manufacturer RK. Output Screw LD Ratio Main Motor wInverter Ø45 700mm 900mm 1200mm 2000mm Ø55 Ø65 Ø90 60kghr 100kghr 150kghr 350kghr 301 30HP 40HP 60HP 125HP EH45T EH55T EH65T EH90T EH120T Ø120 3000mm 440kghr 200HP EH150T Ø150.

Blown Film Machine Optional Devices. Techno FLEX Blown Film lines for the production of multi-layer film 3. 3 Calculate the area of the die.

Blown Film Machine MONO LAYER BLOWN FILM MACHINE EH45TEH150T Model Screw Dia. Cast film extrusion orients molecules in the machine direction only producing a large difference in machine and transverse directional properties. MD machine direction TD transverse direction LD ratio of screw.

Gregory See also Blown film Blown film vs the cast film process Blown film air cooling Centrifugal fans Internal bubble cooling The effects of molecular structure rheology morphology and orientation on. Blown Film Calculations April 14 2015 Amy Laird. 51 Introduction to Blown Film Extrusion.

Dynamic Modeling of Blown-Film Extrusion H Fig. Blown Film Processes and Troubleshootingand Troubleshooting The Ultimate Quality Control Tool Presented by. Need of the Hour to Control Environmental Burdens 65 Figure01 depicts that whole process of blown film extrusion can be analyzed with distinctive and important units as depicted in table01.

Engineering Works Delhi India Established ourselves in 1972 since then we are engaged in manufacturing supplying and exporting of a precision engineered range of Plastic Processing Machines and blown extrusion machines are known as plant like Multi. Studies on Blown Film Cooling 36th Annual Technical Conference SPE Volume XXIV page 476 1978. Working of Blown Film Extrusion Machine.

Machine Direction Asymmetrical MD Wrinkle. Film edge trimming for making two single layers of film. Blown film lines require lower melt temperatures.

The most common ones today are the combination of a 45mm extruder together with a garbage bags normally a 55mm outer layer normally 12-20. Blown Film Lines for Higher Output. Blown Film Properties Purchasing Production Maintenance Raw Material.

Blown films provide a better balance of properties between the machine and transverse directions. SmartFlex Blown Film lines 1 3 and 5 layers characterized by a competitive investment level maximized flexibility for different applications recipes power consumption reduction functional and compact layout featuring frames modularity TechnoFlex Blown Film lines for the production. Film Extrusion Manual iii Preface Film Extrusion Manual is the result of four years of intensive team effort to update the 1992 publication.

Blown film extrusion is also used in the manufacture of products from PVC. An operator can become so familiar with a given film line that problems are solved intuitively but training new. As a result it has good clarity.

Short neck long neck Blow-up Ratio BUR TD MD. Area of the die bubble Flow rate at die frost line Line speed strain rate Changing the strain rate Draw down ratio Questions. Though PVC has limited thermal stability it has good melt strength which lends itself nicely to blown film extrusion.

Paul Waller President Plastics Touchpoint Group Inc. In blown film extrusion molecular orientation of the polymer is achieved in both machine and transverse directions yielding a film with biaxial properties. Nip rolls to provide web tension adjustable speed Edge trimmings are would up on two separate cassettes.

PVC is an amorphous polymer glass transition temperature 220 F 105 C. The delivery of high melt quality is a performance goal not only of screw but also of any well-designed extrusion die. Coextrusion of blown film Coextrusion is the extrusion of multiple layers of material simultaneously.

Blown film extrusion is the most important process for the production of plastic films ranging in thickness from 05 mm to as thin as 5. Blown film extrusion is the most important process for the production of plastic films ranging in thickness from 05 mm to as thin as 5 μm according. Edge trimmer cutting blades.

1Schematic of blown Jzh extrusion a circumferential tension on the bubble-tube. Auto Loader Hopper Dryer Surface Treater Air Compressor Melt Pressure Gauge Temperature Probe Chiller PB45PB75 PP BLOWN FILM MACHINE Model Screw Dia. Output Screw LD Ratio Main Motor wInverter Ø45 400mm 600mm 800mm Ø55 Ø65 35kghr 60kghr 75kghr 301.

60 CaC03 Added 100 Recycled Material Used The A-B-A blown film machine consists of two extruders normally of two different sizes. Bandera Blown Film extrusion range includes. Good melt quality means that no flow lines are created that may result in a visible or structural defect in the film.

The blown film process can produce a wide range of film sizes from the same die. Bandera Blown Film extrusion range includes. Coextrusion of blown film Coextrusion is the extrusion of multiple layers of material simultaneously.

Bandera Blown Film extrusion range includes. 51 Introduction to Blown Film Extrusion. Blown Film Machine MONO LAYER BLOWN FILM MACHINE EH45TEH150T Model Screw Dia.

Adopting Best Practices in Blown Film Extrusion Process. Given therefore a single screw machine is being described that has a screw of diameter 60 mm and a length of 24 screw diameters that is a LD ratio of 241. Blown Film Basics The goal of this brochure is to describe specific defects that can appear in tubular blown film and to suggest probable causes and solutions.

Three Layer ABA Blown Film Machine 30 Stronger Film. Blown Film Machine Optional Devices. μm according to Butler 1.

Blown film lines are used to make shrink wrap films.

Blown Film An Overview Sciencedirect Topics

Make Your Own Injection Molding Machine Make Diy Molding Diy Projects Homemade Machine

Wenzhou Aoxiang Packaging Machinery Co Ltd

1 300 Hobby Business Plastic Injection Molding Machine Molder Press Free Mold Ebay Refurbi Plastic Injection Moulding Machine Plastic Moulding Diy Molding

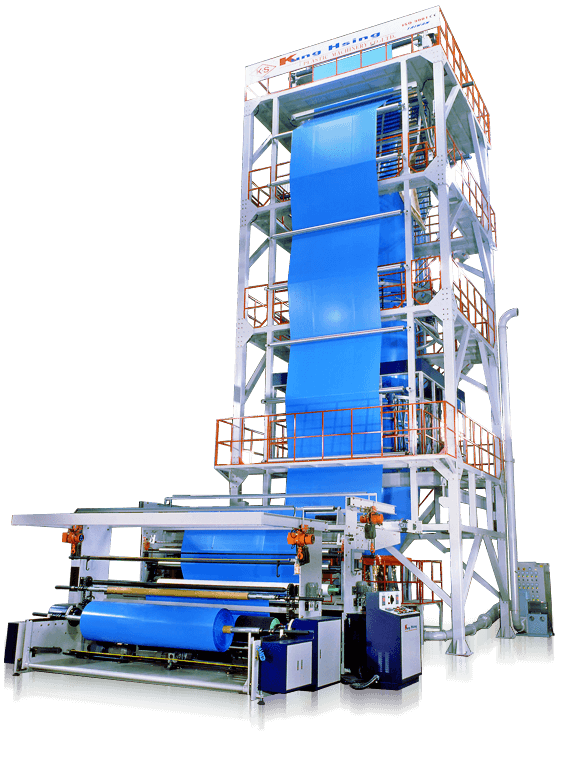

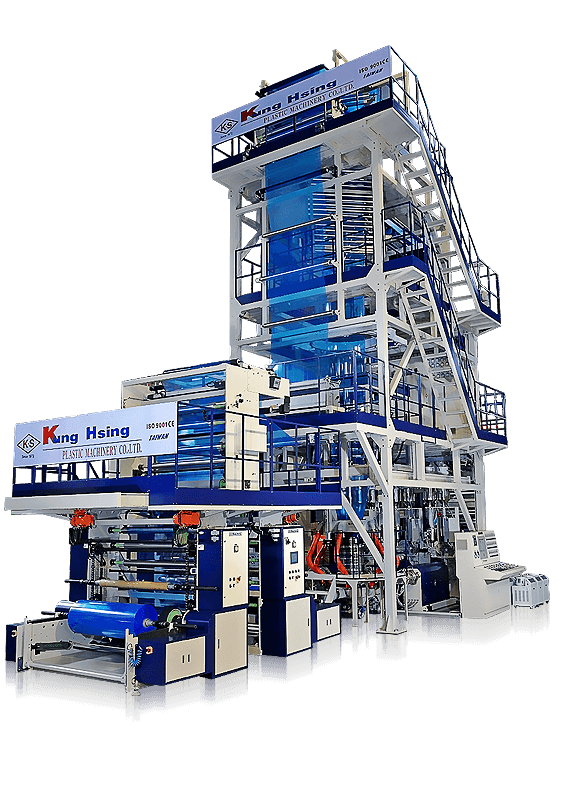

High Performance Extrusion Machinery Kung Hsing Plastic Machinery Plastic Blown Film Machine

Blown Film Bandera Plastics Extrusion Italy

Shubham Extrusion Technik Private Limited Ahmedabad Manufacturer Of Blown Film Plant And Multilayer Film Plant

1 Schematic Of The Film Blowing Process Download Scientific Diagram

Blown Film Extrusion Process Explained Amcor Inc

Wpc Extrusion Wood Plastic Composite Machine Wpc Profile Extrusion Line Pvc Wood Plastic Machine Wpc Profile Producti Wood Plastic Composite Extrusion Wood

Blown Film Extrusion Line Varex Ii Windmoller Holscher For Hdpe For Pe Multilayer

Wenzhou Aoxiang Packaging Machinery Co Ltd

High Performance Extrusion Machinery Kung Hsing Plastic Machinery Plastic Blown Film Machine

High Performance Extrusion Machinery Kung Hsing Plastic Machinery Plastic Blown Film Machine

Blown Film Bandera Plastics Extrusion Italy

How To Make An Interesting Art Piece Using Tree Branches Ehow Edible Oil Cooking Oil Rice Bran Oil

Brummble Side Front Paper Toys Bramble Paper